Products List

Contact Us

Contacter:Mr. Wu 13906117130

Tel:086-0519-88909773

Fax:086-0519-89189773

Website:www.jxdry.com

Email:czjxdry@foxmail.com

Heat source equipment series

Gas fuel hot air stove

Detailed description

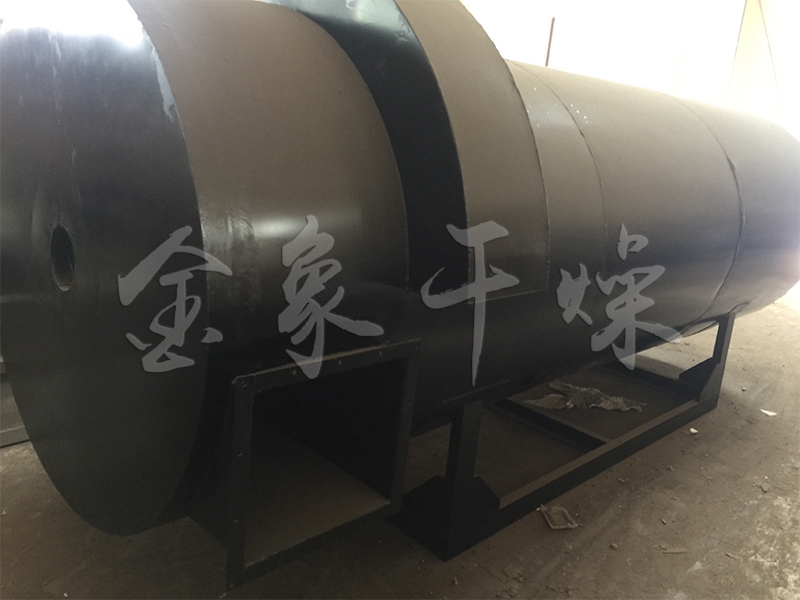

Gas and oil hot air stoves are the ideal hot air equipment in the fields of drying, reaction, calcining and heating. They can be used in combination with various drying equipments . They can provide high clean hot air with different temperatures for drying systems, and can burn natural gas, city gas, CBM, gas, gas and light diesel, bio-oil, residual/heavy oil.

Due to the relatively clean hot flue gas produced by direct combustion of light oil and natural gas, in industrial production, a direct fired type is usually used, ie direct hot flue gas generated from fuel or gas is directly used as a heat medium.

Equipment Composition The

direct-fired gas-fired, oil-fired hot air furnace mainly consists of a valve assembly, a burner, a combustion chamber, a secondary air distribution system, and a control system.

How it works The

fuel burns through the burner and produces high-temperature gas. The heat of the high-temperature gas is transmitted to the heated air by means of a hot-air stove with enhanced heat exchange measures. After the high-temperature gas is emitted, the temperature is lowered to 250° C. and discharged to the atmosphere. The heated air is forced into the hot blast stove through the optional blower. When the heat is absorbed, the temperature rises to the rated value and is sent from the hot air outlet. When the hot air temperature reaches the upper limit of the rated temperature, the burner will automatically stop burning or automatically switch to a small flame. When the temperature of the hot air drops below the rated minimum temperature, the burner will be re-ignited or burned. The temperature rise can be adjusted by adjusting the opening of the intake valve.

Product Features

1. Clean air and high thermal efficiency. Auxiliary equipment less, low investment costs, good operating environment;

2, adjustable hot air temperature, continuous heating air temperature stability;

3, easy to operate, manual / automatic control;

4, with automatic ignition, load regulation and flame detection, alarm Features.

Technical specifications

| model | Burner model | Fuel quantity kg/h | Heat supply 104kcal/h | Dimensions L×W×Hmm | Hot air outlet L×Wmm | Total weight kg |

| RLY1 | RIELLO.G3/DL3FS | 1.3-1.6 | 1 | 1200×1200×1600 | Φ200 | 460 |

| RLY4 | RIELLO.G10/DL10FS | 5-6.5 | 4 | 1700×1300×1600 | Φ250 | 850 |

| RLY10 | RIELLO.G20/DL23FS | 13-16 | 10 | 2300×1568×1870 | Φ300 | 2200 |

| RLY20 | RIELLO 1G/DL34FS | 26-32 | 20 | 2800×1568×1870 | Φ400 | 2670 |

| RLY30 | RL50/DL55FT | 39-48 | 30 | 3400×1568×1870 | Φ450 | 3060 |

| RLY40 | RL70/DL75FT | 52-64 | 40 | 4440×1768×2070 | Φ550 | 5600 |

| RLY60 | RL100/DL100FT | 78-96 | 60 | 5140×1868×2070 | Φ600 | 8460 |

| RLY100 | PRESS 4G/DL 120FT | 130-140 | 100 | 6440×2480×2300 | 550×600 | 12800 |

| RLY160 | P300/DL250FT | 200-270 | 160 | 7470×2920×3480 | 750×900 | 15780 |

| RLY200 | P300/DL300FT | 260-300 | 200 | 8175×2920×3480 | 750×900 | 18500 |

| RLY360 | G1510 | 480-620 | 360 | 9300×2920×3480 | 21000 |

Prev:没有上一篇